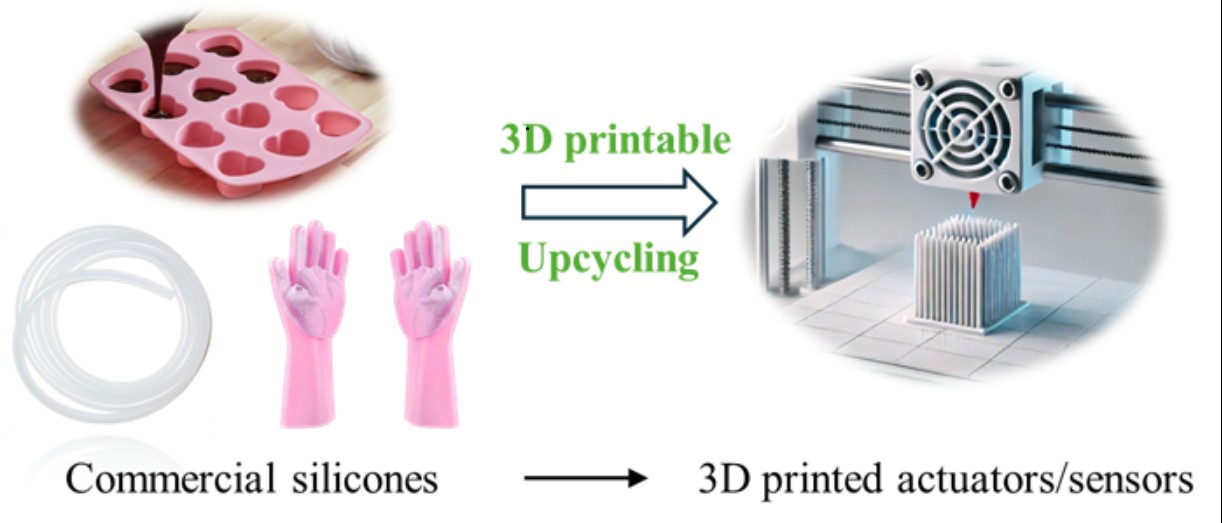

3D printable upcycled silicone commodities

Introduction

Silicone elastomer is a versatile material used in a wide range of applications (i.e., medical and healthcare, adhesives, electrical insulators, etc). The attributes of flexibility, durability and biocompatibility make it a suitable material candidate in soft actuators & sensors. However, its crosslinked network prevents easy recycling or reuse. Upcycling silicone waste into 3D-printable materials presents a sustainable and innovative approach to manufacturing. Traditional silicone disposal poses environmental challenges due to its durability and resistance to degradation. By transforming discarded silicone into printable resins, this process promotes a circular lifecycle in additive manufacturing.

Objectives

To address the issue, this project innovatively aims to achieve 3D printable upcycled silicone commodities. We will explore methods for upcycling commercial silicone products, optimize parameters to enhance their printability, and identify potential applications in actuators and sensors for sustainable robotics.

We are looking for motivated MSc students who want to contribute to the development of 3D printable sustainable materials with a dynamic and interdisciplinary mind.

Appropriate for: Master Thesis, Semester Project

Supervised by: Prof. Hedan Bai (), Dr. Wusha Miao ()

References

(1) Mazurek, P.; Vudayagiri, S.; Skov, A. L. How to tailor flexible silicone elastomers with mechanical integrity: a tutorial review. Chemical Society Reviews 2019, 48, 1448-1464.

(2) Stefano, M.; Rafael L.; F, B, Coulter.; André R. S. 3D-Printed Architectured silicones with autonomic self-healing and creep-resistant behavior. Advanced Materials 2024, 36, 2306494